A knife holder for a child

The context

Lina is a 5 years old girl when we meet her for the first time. She was born with a malformed right hand equipped with two fingers. One of these is weak. She cannot flex both of her fingers, but only move them laterally as a kind of needle nose pliers. And she is very comfortable for most of everyday life activities… except for some actions that she cannot perform. And an example is holding a knife. Her parents are used to help her cutting meet, and she is used to push rice to the fork (which is handled by her left hand) with her two fingers.

But now she has to have lunch at school, or sometimes diner in a restaurant, and she probably feels not so comfortable in front of other children. Thus Eric her father asks e-Nable community if someone can help in developing a kind holder for Lina.

Modeling of a fitting socket

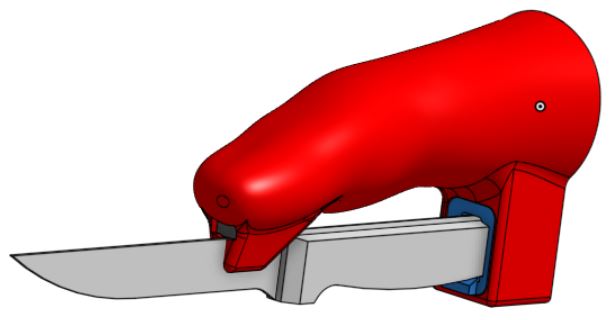

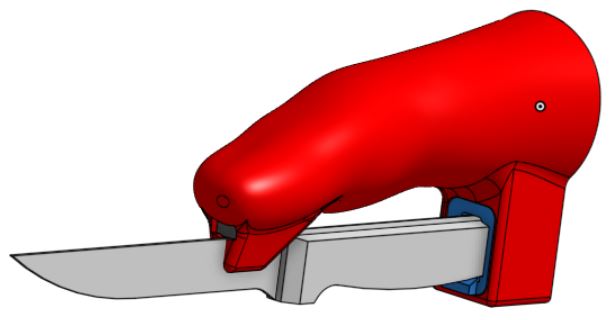

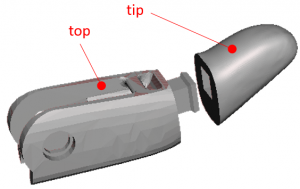

After a first meeting with Lina and Eric, we consider that a standard e-Nable hand cannot fit the need of Lina, and we decide to develop a very dedicated knife holder. It will be made of a socket in which Lina can insert her right hand, and some specific shapes where she can fix different kinds of knives.

Hand casting

The first operation is to get a model of Lina’s hand. This is done by casting her hand in pink Alginate to get a positive plaster copy.

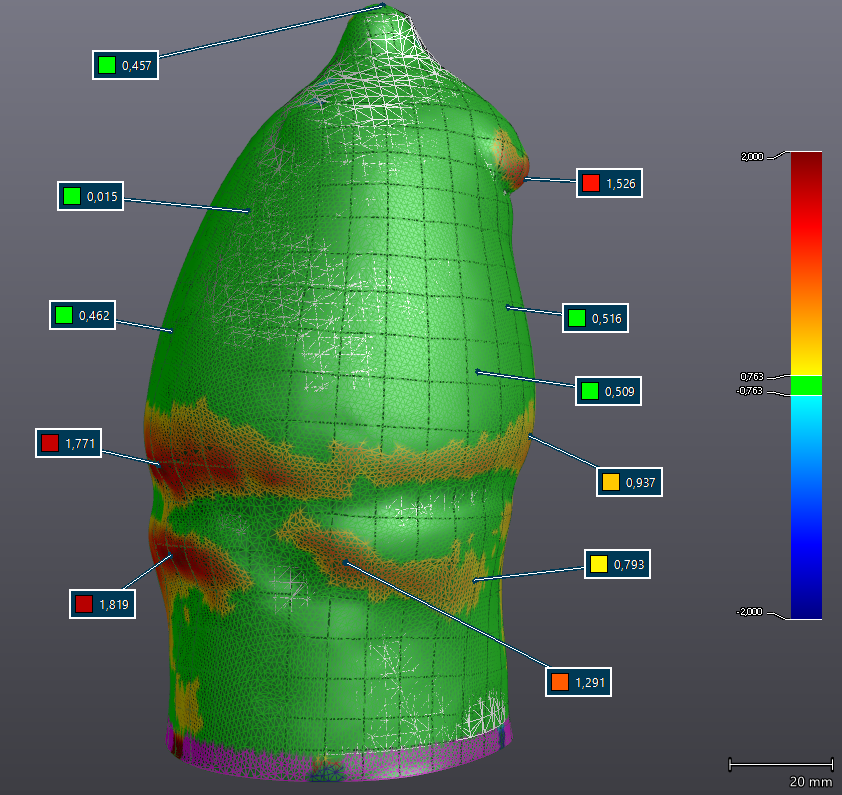

Shape modification

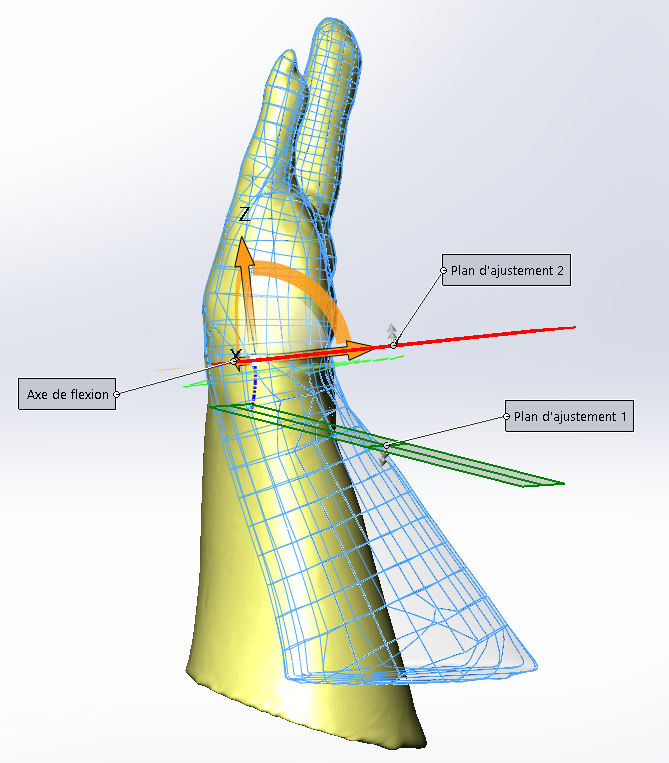

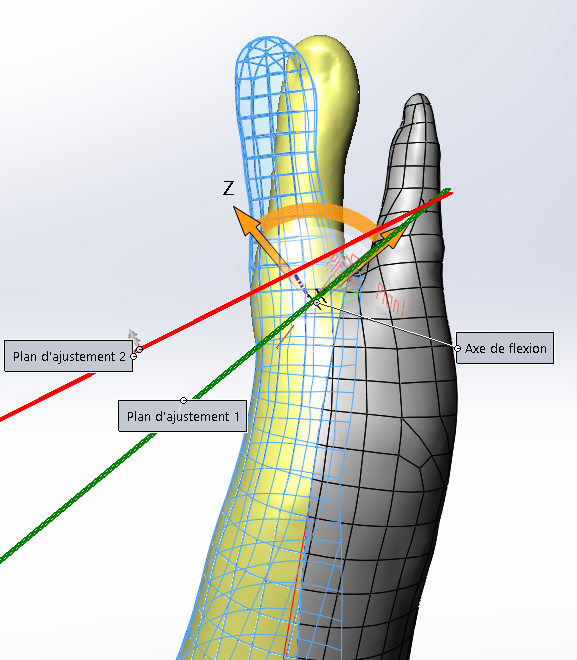

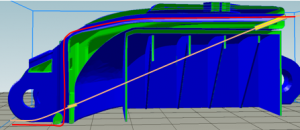

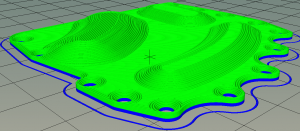

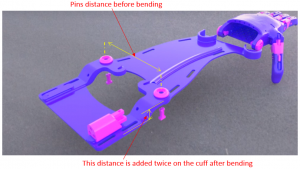

Unfortunately she bent her wrist during casting operation. After the 3D scanning and reverse engineering process that leads to a clean digital model, the next operation to get a proper model usable to make a comfortable socket is then to unbend the CAD model. This is performed thanks to a specific “flexion” function available in SolidWorks. This allows to put the hand inline with the forearm, and also to put the two fingers closer to each other.

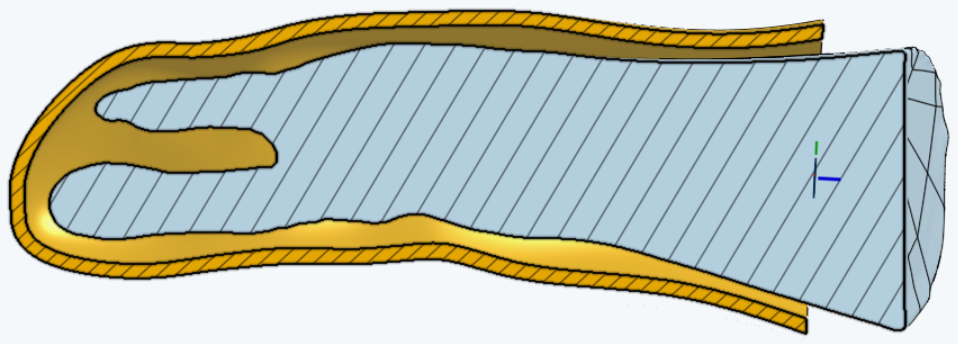

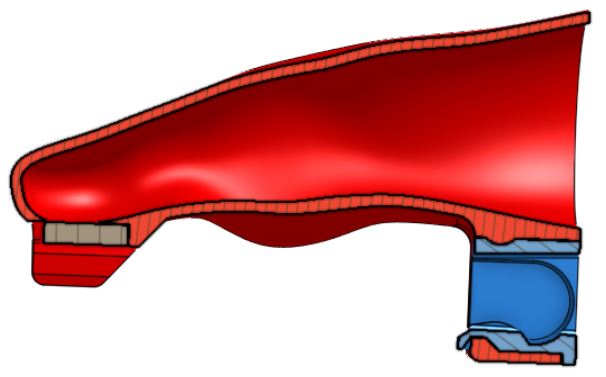

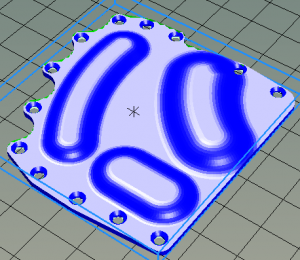

Design of the socket

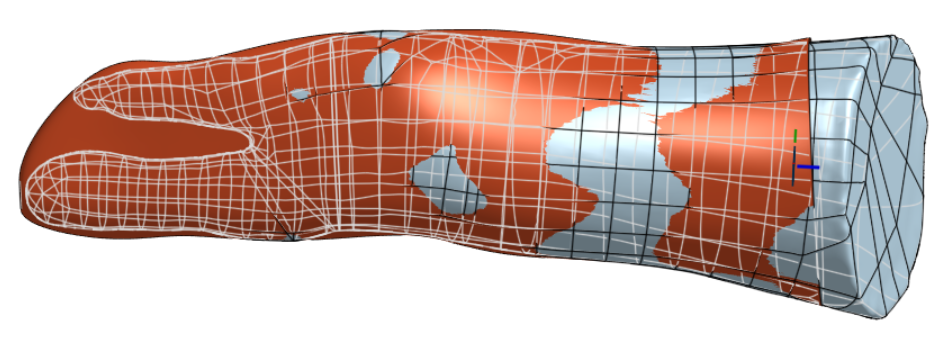

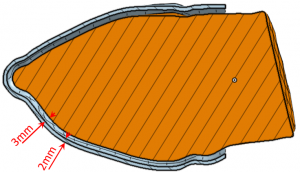

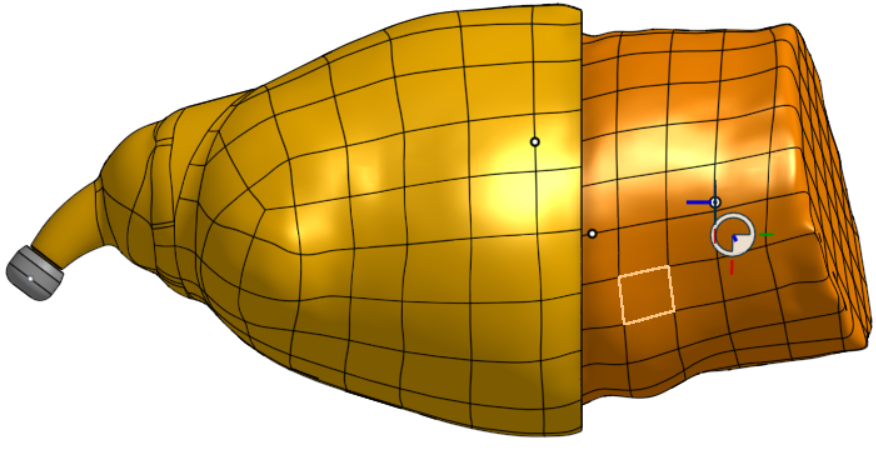

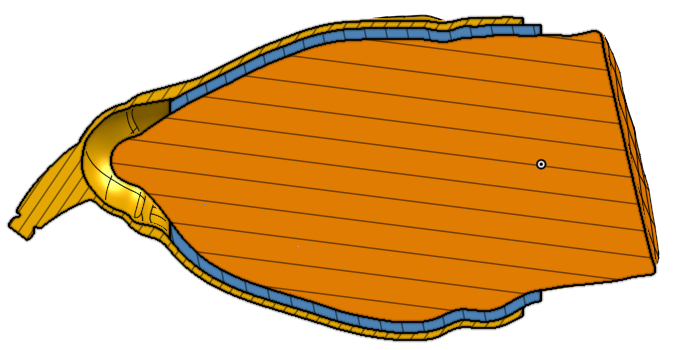

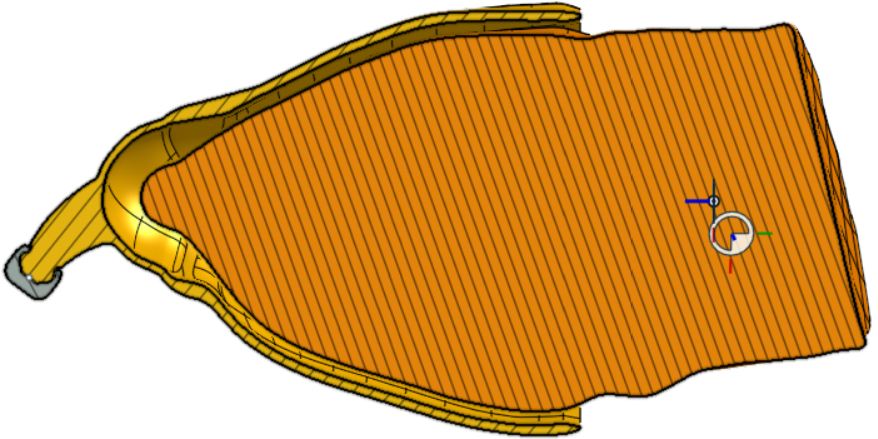

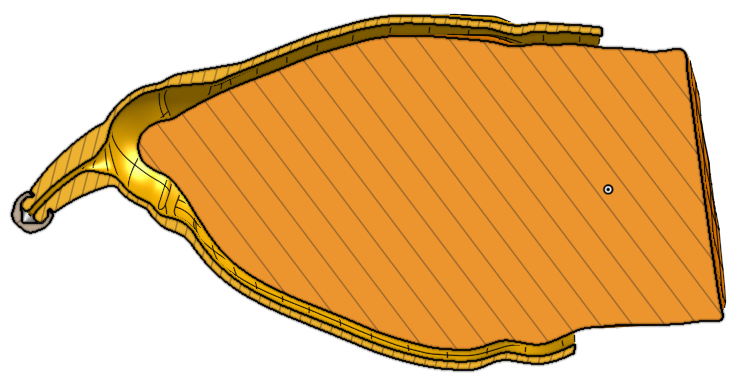

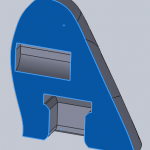

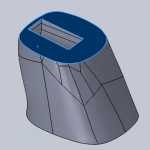

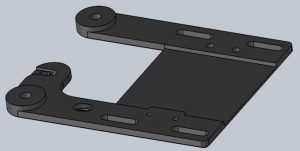

The next step is to design the socket. We come back in our collaborative CAD software, Onshape, to draw a few sections and build a “loft” that approximately fits Lina’s hand. Then two offset operations of surfaces lead to the inner and outer shapes of the socket, with 3mm gap dedicated to put a comfortable 3D fabric that can absorb moisture and can be easily removed for washing.

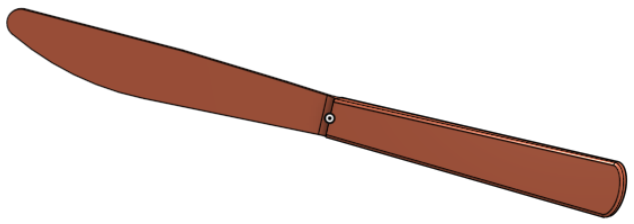

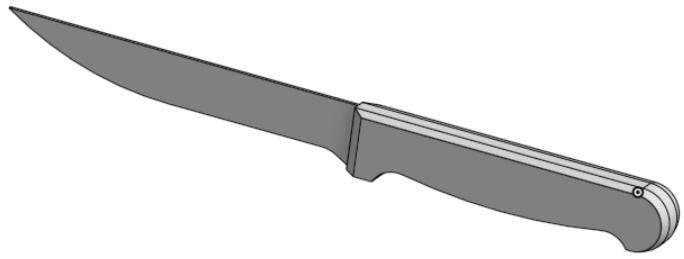

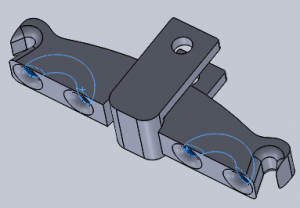

Designing the knife holder

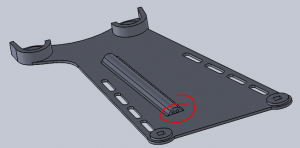

The input information for designing a knife holder it to have an idea of the types of knives that will be used with this device. Eric, Lina’ farther, provided two CAD models (he drawn by himself) of knives available at home: the “knife to push” and the “knife to cut”.

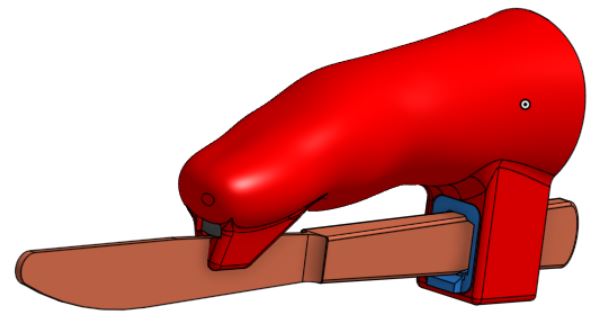

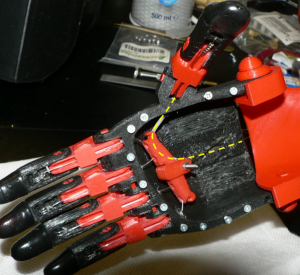

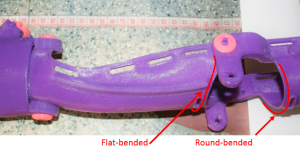

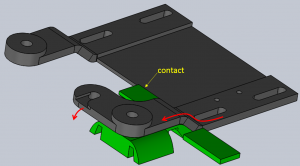

Then we started with the idea of fixing the knife handle in a flexible interchangeable part that should fit both types of knives, and to add a simple slot to center the blade. In the first prototype the blade has been tied with adaptive strap made of Velcro type band (ID-Scratch).

After validation of the orientation and position of the knife by Lina, for the second version the strap was replaced by a simple neodymium magnet. You will find below a photo of the first version in test (pushing knife), and several CAD views of the last version.

And then…

Lina is happy, she can eat without asking for help to her classmates;

Eric is happy, Lina eats now without pushing noodles with fingers.

Eric asked for advice because (and that’s also good news!)

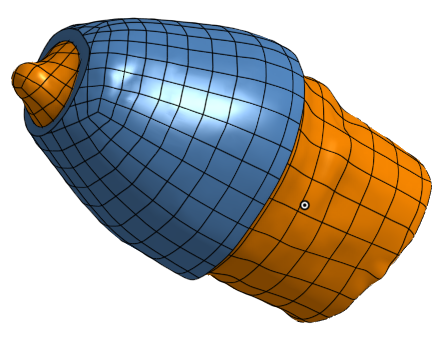

- he is in the process to learn how to design with Onshape. He already made a new insert (the blue part on screen shots above) that will fit another knife handle.

- And he is in the process of buying a 3D printer and we hope him to become a new maker within e-Nable France community 🙂

The CAD models are available for inspiration, adaptation to other cases, and hopefully for improvements under cad.onshape.com, if you have an account (free for non profit activities and public models), you just have to search for “Team Gre-Nable : knife_holder” among the public models.

Please just let us know if you design an adaptation of this!

Recent Comments