About Us . How we Work.

More about our team, our methods and what we created to develop and print and offer better prosthetics to applicants.

Who is “team Gre-Nable.fr” ?

The team was originally created around three makers, all driven by the same willingness to provide functional solutions to prosthesis applicants. Then other makers, approved by e-Nable France, joined our dynamic team.

Marie Laure

Associate Professor

Marie-Laure is Associate Professor of Mechanical Engineering. She teaches at the Engineering Institute ‘Grenoble-INP Génie Industriel‘.

Patrick

Retired & Geek

Patrick spends his free time creating websites, hacking electronic modules and creating prosthetics for e-Nable community (3Dprinting and CAD design).

Younès

Research & Training Associate

Gérard

Retired Professor

Philippe

Researcher & Professor

Philippe is Senior Lecturer and Professor specialized in product design at Grenoble-INP Industrial Engineering (Engineering Institute).

Fabien

Mechanical Engineer & PHD

Fabien joined the group after a PhD in mechanics, specialized in friction and acoustics. He is passionate about the field of prosthetics and works to make them more accessible to people who need them.

Camille

University Platform Engineer

Camille is poly-graduated as Electronic & System Data Processing Engineer, and Mechatronic Engineer. He brings his great knowledge for our electronic-assisted hands and all projects based on microcontrollers. He is also a talented trumpeter.

Arnaud

Software Engineer

Arnaud is a software engineer with a strong interest in mechanical design. As a 3D printing enthusiast, he can combine all his passions to contribute to Gre-nable.

Matching, Analysis

The matching process between a prosthesis applicant and our team is made by the association e-Nable.fr depending on the geographical location where the applicant lives and the short-term availability of the team. Our team organization makes it easier to work on several projects at the same time, thanks to the sharing of tasks and resources between the team members.

Once matched with the recipient, the team will set an interview to refine all measurements (previously sent), to perform a cast and / or a scan of the arm. The discussion between the team and the beneficiary makes it possible to define which type of hand will be chosen and to envision the adaptation works to be specifically done.

In addition, fortunatelly in Grenoble, we have developed fruitfull relationships with the medical community (mainly in the orthopedic sector) with whom we collaborate on specific cases.

Adjustment & Development

Depending on the kind of support for the prosthesis (carp or forearm) and its general appearance, we study whether to use a standard e-Nable hand (like the Phoenix model) or whether to adapt it with a special designed receiver derived from the molding of the carp and its 3D representation after scanning.

The development is then realized in shared mode </ em> thanks to a very sophisticated and powerful web-application for CAD, freely available from the editor for the makers ( Onshape.com < / em>).

Several releases are often necessary to achieve an operational solution. Each release is usually printed to validate the CAD model in collaboration with the recipient. It is improved when necessary to obtain the prosthesis really fitting the need and the morphology of the concerned person.

Delivery, Joy of Offering

At the end of several prototypes, the final release which integrates all the remarks from the beneficiary is delivered to him. During this event, it is a real moment full of emotion and joy shared by everyone.

A follow-up is carried out with the wearer of the prosthesis to know if the prosthesis fulfills its role, if it will require further evolutions or repairs.

Paired children are guaranteed to receive new prostheses during their growing, always via the e-Nable France association .

OUR LAST PROJECTS

Our Printers and Partners

Members of team Gre-Nable.fr are also members of the charity organization (e-Nable France) and are full active members of the unique Grenoble’s hackerspace : Open Laboratory Grenoblois (a.k.a LOGre).

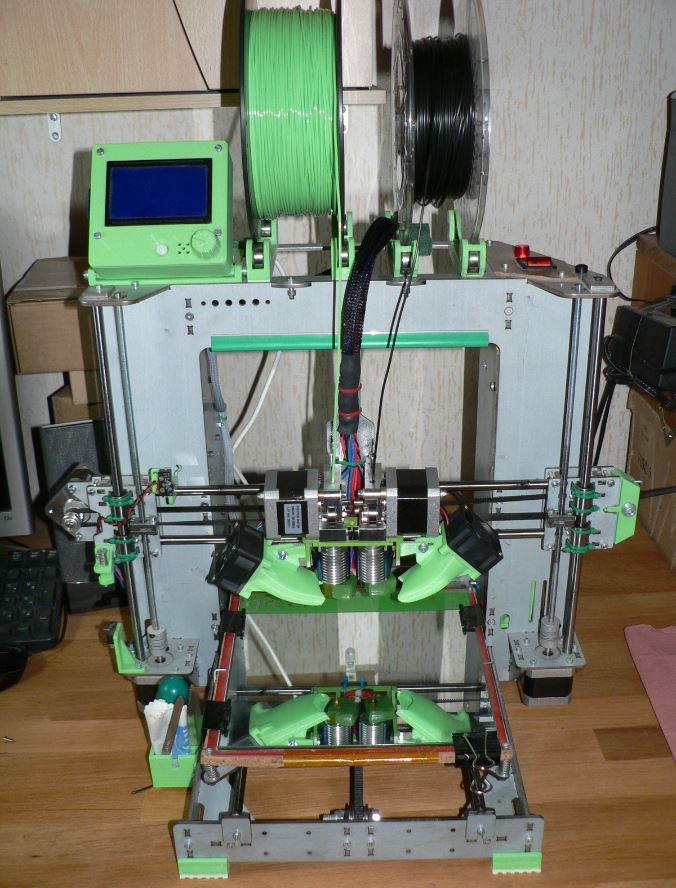

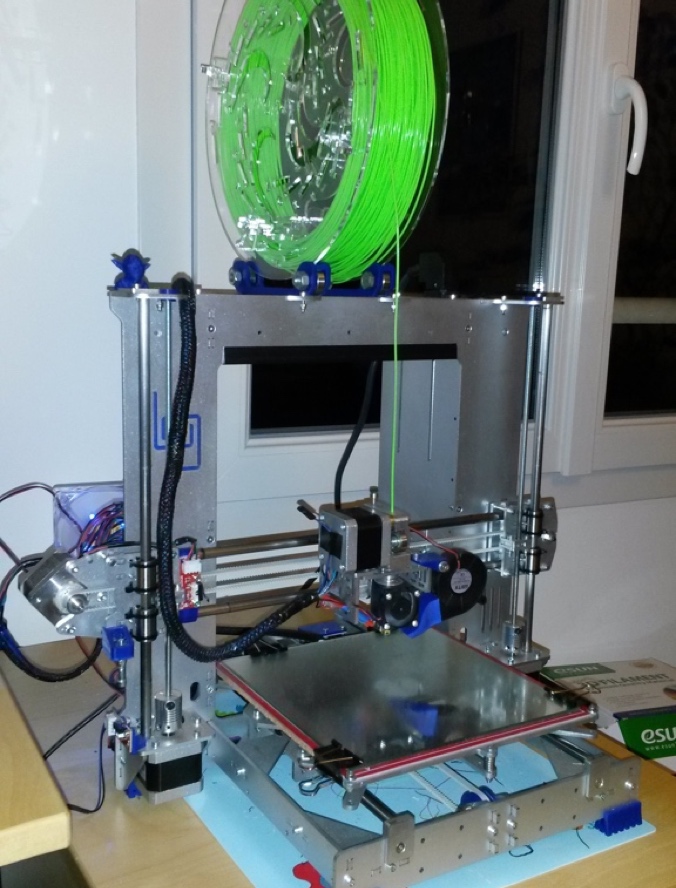

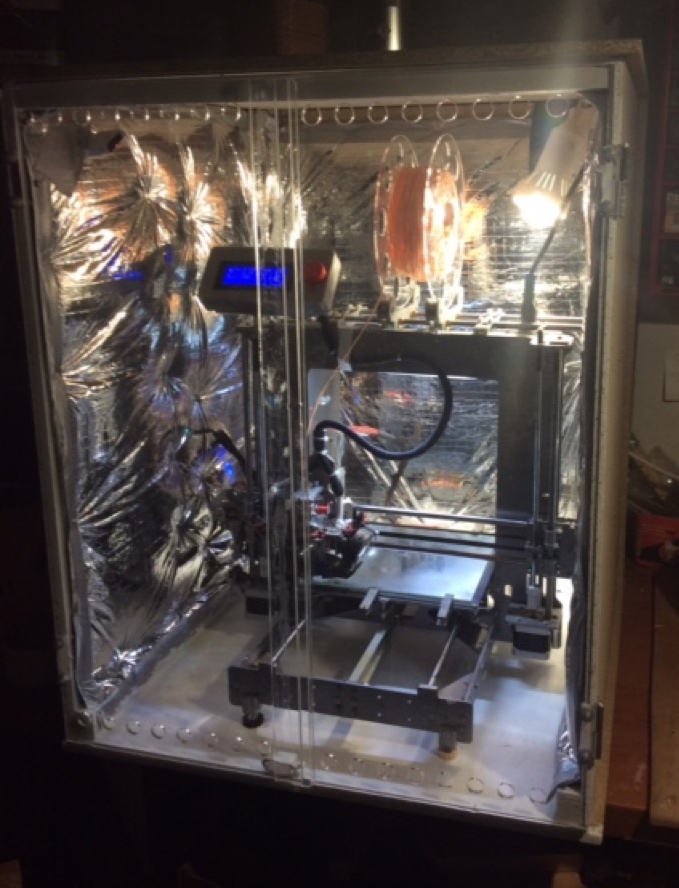

LOGre, as a hackerspace, is to say an association welcoming everybody intersted into technological diversions and DoItYourself of all kinds : electronics, mechanics, ecology, laser cutting, 3D printing, software and product design. Everything designed is by evidence freely available and published under the ” open source ” concept. Among all the projects initiated and carried out within the association, a major one was the design and manufacturing of a 3D printer (a.k.a LOGresse). In just a few years, the printer was built to more than 90 units, including foreign makers who also brought their personal touches to the basic model. That project naturally brought us together and motivated to join the worldwide charity movement “enablingthefuture“.

We are continuing to develop this printer and the production files, published according to the Open RepRap concept, can be downloaded from the association’s wiki, and whose CAD design files are available on the Onshape.com website.

Our hands and arms that we print are directly produced with this “handmade” printer.

The “Green Show” made by Philippe in dual extruders configuration

The “Blue” release made by

Marie Laure

The “Silver Shadow” made by Patrick in its winter house.

Our Partners’ Logos

Contact us

to know more about our works and to stay in touch with the community.