Why we are using Onshape for designing our projects ?

Most of us, makers of the e-Nable community are not professionals of mechanical design and we are learning this new activity the more we could.

To ease the learning curve, we need to access the most simplest but powerful tools.

From the various posts published on blogs or facebook, most of us are using open software or free version of commercial products whilst very few are using their professional package.

In our case we experiment various software until we reached an obvious agreement to use the same. In the past we were using free and open software like Openscad, freecad, some education license for Solidworks, or free version of commercials products like 123Design or Fusion 360 (Autodesk).

Every software has advantages and odd points, but there were also common issues:

- Continuous upgrades to be installed

- Not always the right level of power from our machines

- Disk capacity always increasing

- Often crashes, blue screens, white screen of death ….

- Huge files to exchange with friends

- Often no sharing capabilities to work on the same project with friends.

There is no heaven in software, still true, but we can find a better life solving most of the issues … unfortunately creating new ones.

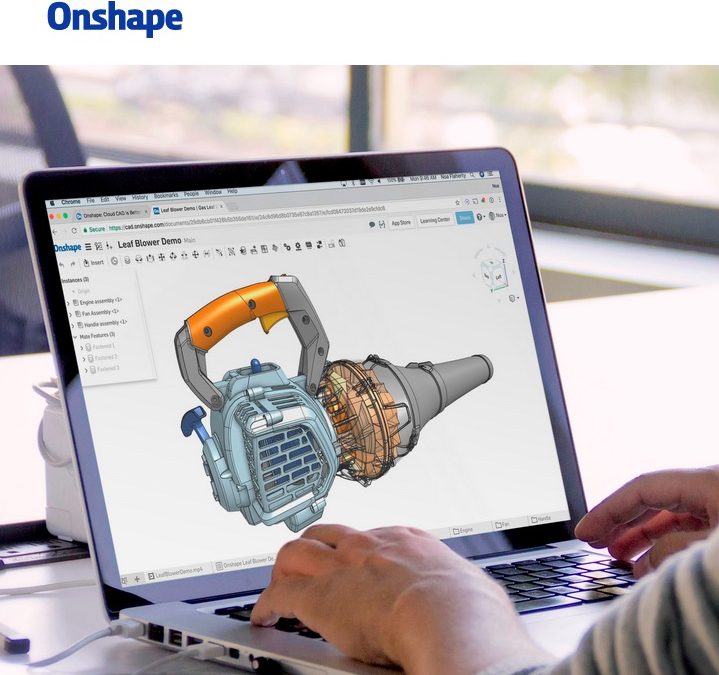

For more than a year, team Gre-nable.fr and friends have moved to using Onshape (from Onshape.com). This is a web application, accessible with all browsers, professional grade, with almost all what we need to design our prosthetics.

I will rephrase the 8 points cited by Onshape’s marketing team because I fully agree with them and they were the trigger to write this memo to let our community knows more about it and to consider it for future works.

We are using Onshape because:

- Onshape is AGNOSTIC – As Cloud based CAD, it works across Android, iOS, Microsoft Windows, Apple MacOS and Linux – and with phones, tablets, laptops and desktop computers. No more issue with applications that are missing MacOS !!

- APPLICATIONS AND UPDATES – No more updating software release with regularly crashes because your system is not 100% sanitized or because the release has not been fully tested by the development team. Everybody knows (and suffered from) this situation!! Onshape is updating his release once a month with new features and bugs fixing. You don’t even see it, they have to push a message in your mailbox to learn about new features.

- COLLABORATION – Teams can instantly communicate about design changes and get real-time updates on their colleagues’ progress. The ability to let multiple friends simultaneously work on the same design means that we are more efficient. Counterpart to free license, all our projects are public but who cares in the open world ? We are more than happy if other e-Nable volunteers will copy and improve our designs.

- COST MANAGEMENT – The time to buy more powerful computers, more disk space, more memory, is over. We just need a good Internet access (dsl is great), the right graphic card and a clean installed OS. No need to back up tools as well.

- MOBILITY – This is not a strong argument for us as we are mostly working from home, but you can create and edit your designs on your phone or tablet, carrying your CAD system with you wherever you go. This is nice to show your design during seminars, meetings, shows where you will meet other members of the community.

- SCALABILITY – This criterion is not applicable for us, whilst the free users should not benefit from this ability to require more power for complex design or rendering.

- SECURITY – We delegate to the web application the tasks of backup’ing our works, keeping always a safe copy. The developments are journalized so it’s always possible to revert to an older version. The concept of releases and branches is sophisticated and easy to use.

- SIMPLICITY – The entire product is based on an internal scripting language ‘featured script’ and the cleverest of us will be able to automate some tasks by editing their own scripts. The basic rules of designing are pretty simple, lots of tutorials exist on Youtube and (as usual) a community is helpful on the support blog.

Of course I have considered the PROS and there are few CONS !

CONS#1 : For the time being, Onshape is still young and is not as features rich as Solidworks or Fusion360. For instance, we needed to use Fusion360 to transform Quad mesh into TSplines, to be then imported into Onshape (see explanations in the post “Adapter une emboiture pour une prothèse“)

CONS#2 : Onshape is said “secure in the cloud”. This is true as long as the company will exist. I bet this company is well founded and will last as long as me. I’m not sure this is a concern, the reality is that since the good ol’ time when I started microcomputing with Apple ][, I lost a lot a important information when changing from one technology to another, and I survived this information chaos. So, the PROS win against the CONS.

At that point, you can think I could have some interest in pushing Onshape on the front scene !! Unfortunately I have none. I’m only enthusiastic by using this powerful tool, and I hope others will do the same, letting us share our projects to build better prosthetics for those who need them.

All our designs are freely accessible for copy, modification (once you will create your own copy) and for sharing whatever the distance is between us.

How to get an account? Nothing could be easier: create an account from the landing page (www.onshape.com), let them few information and that’s it! They are not pushy guys once they understood you will not buy the full paid license. You will receive emails announcing new features, free webinars …

The team behind Onshape is issued from prestigious CAD firms under the leadership of Solidworks’ founders.

To find our project, the usual method is to login at https://cad.onshape.com with your credentials, then to enter the keywords in the Search tools windows.

To find the complete design of our 3D printer, the key words is : “LOGresse”.

Onshape will display few projects including LOGresse within the name, the first one displayed “LOGresse Main” is the correct one, whilst the others are projects of various parts built outside the main stream.

You will be able to visit all ‘Part Studio’ and ‘Assembly’ but to see the scripts, feel free to make your own copy of the project and then, you will have 100% control on each elementary CAD primitives. You will be able to download STL files for 3D printed pieces and DXF files for cutting plates of metal.

For the design of the prosthetics, the keywords to find them will be released in each post of our blog when we will deliver the full details. Coming soon.

Recent Comments